In this article, I’ll give some tips for how to price your DIY woodworking projects to sell as a side hustle. For a little context, I run DIY Projects with Pete in addition to Think Entrepreneurship. I make YouTube tutorials and detailed plans to inspire other DIYers to just get out and build with wood, metal, and concrete.

Many of my subscribers have written to tell me that they’ve had success building projects based on my plans and selling them for a little extra income—which is great! I don’t normally sell the projects that I make because I focus on the online part of the business. But I know that deciding how to price your DIY woodworking projects can be a difficult question. It’s a combination of materials and labor (your time), overhead, demand, and other factors. It can sound complicated, but it really doesn’t have to be difficult.

Let’s get into it!

Basic formula

For most DIY projects, from woodworking to concrete to crafts, you can tweak this basic formula:

MATERIALS + 10-30% OF MATERIALS + HOURLY RATE

Within these variables, there are several more items to factor in: overhead like rent, utilities, and maybe insurance, taxes, tools and maintenance, skill level, turnaround time, etc.

A lot of this will also depend on your level of side-hustle. If this is just a hobby to break even, a side-hustle for extra cash, or working toward making this your full-time gig. For the sake of this article, we’ll mainly follow option two, a side-hustle for extra cash.

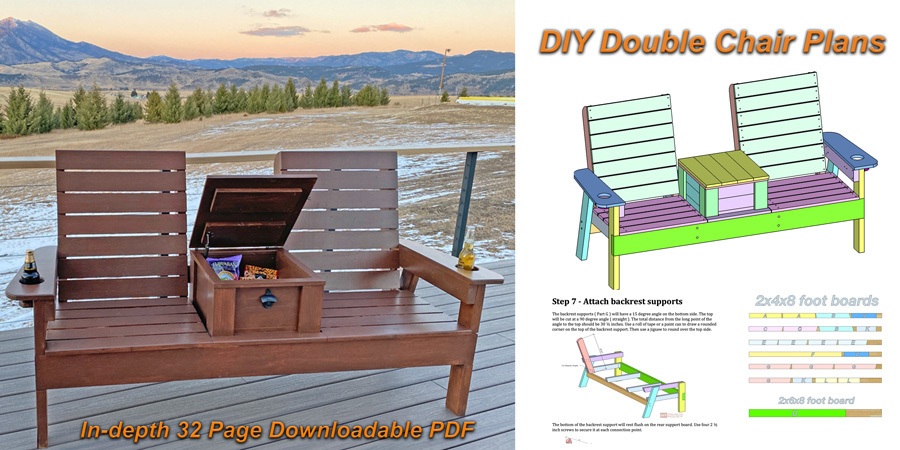

Scroll down for a bunch of project ideas. As an example, a patio chair could sell for around $200-250, and a double chair around $300-400, depending on your market and materials. One of my most popular DIY projects has been the farm table. It costs about $200 in materials and could sell for over $1000 in the right circumstances.

Materials

This is the most straightforward part of the equation. I always sketch out my project to get a good estimate of what I’ll need. How many 2x4s or other boards, hardware like screws or hinges, finishing materials like paint or stain. When choosing your wood at the lumber yard, you’ll need to pick through it yourself to make sure the boards are good. Look for obvious knots or chunks missing, and make sure it isn’t too warped by looking down the long edge.

Choose wood wisely

Pine is the softest and cheapest, while hardwoods like maple, oak, or walnut get more expensive—and look much fancier. If you’re building a project on commission, be sure to ask what kind of wood they want and be clear about pricing. If you don’t know the retail price for a type of board, you can usually look it up on HomeDepot.com, which should at least be a ballpark estimate even if you’ll buy your wood somewhere else.

Finishing is all in the details

Paints and primers, and stains and polyurethanes, can also vary greatly in price by brand and quality. I’m a big fan of Rustoleum for paint and Minwax for stains. I recommend just picking them up at your local hardware store instead of having them shipped. Be sure to count the multiple products and steps you'll need from start to finish, like sanding, primer, paint, and clear coat.

The finishing details can take longer than building the actual project. Sanding before painting can take a lot of time, especially if you do multiple grit levels. Account for all the time needed to paint enough coats and drying time between coats. Of course you can usually do other stuff while it dries, but it will matter if you have a quick turnaround time. If you’re using an oil-based enamel, they can take a few days to really dry!

A percentage of materials

This usually ranges from 10-30% of the total price of materials. Tacking on an extra percentage helps account for some of the logistics of woodworking: time spent shopping and picking your boards, a few extra boards just in case, loading, unloading, and properly storing the materials. You can also factor in some of your overhead or tools into this number, though your hourly rate can also include overhead.

Hourly rate

This is the least straightforward part about how to price your DIY woodworking projects. It’s about the finished product, but it’s also about your time—how much am I worth? It can be a really big question!

For starters, you’ll want to make at least minimum wage. Hourly rates can depend greatly on your area; in general, prices are higher in cities and lower in rural areas. If you have years of experience and fine techniques, you can charge more. Personally, I’d aim for between $25-80/hr, depending on the technicality of the job. If you’re doing some basic pine construction, it’s on the lower end. If you’re doing computer modeling or laser cutting, using biscuits and laminating, I’d go on the higher end.

Time is of the essence

Keep track of your time as best you can. Remember that things almost always take longer than you think they will. Some of the steps to include are: designing the piece (and any back-and-forth communicating about it, which can be a lot!), shopping, loading/unloading, building, finishing, cleanup, delivering, installing.

How to factor in overhead

Your hourly rate is also where you can factor in your overhead. If it’s just a side hustle, you probably won’t have business insurance and you might be working out of your garage. But you’ve still got tools to buy, consumables like sandpaper and glue, and other things around the shop. If your customer would go to a full-time woodworking shop, they’d likely pay a starting hourly rate of around $85 or more.

If you can estimate your yearly overhead costs, you can estimate a number to add to your hourly rate. Let’s say you have $2,000 in overhead expenses, and would like to work 10 hours a week on your side hustle. 10 hours per week multiplied for the year is about 500 hours. Then, just divide your total overhead amount by total hours. With our numbers, $2,000 / 500 hrs = $4 / hr. So you should factor in $4 per hour to your hourly rate to cover your yearly overhead.

Commissioned work

Word of mouth through friends and family

You’ll need to build a few items first to demonstrate your skills and take pictures. Share them with friends and family privately or over social media, and hopefully you can garner up a little interest. Hopefully, you can get a few commissions for larger pieces of furniture. A quality piece at a friend’s house could lead to more commissions when their friends see how nice it is. Word of mouth is one of the best forms of advertisement, especially for small-scale woodworking.

Commissions are ideal

Working for commissions is more ideal, in my opinion, because you already have a buyer; you’re not just making something and hoping someone will buy it. You will need to communicate clearly and make the item just how they want it. Commissions have the potential to be larger ticket items, like custom shelves or patio chairs, which also means a larger profit for you.

Figure out a budget that you’re both comfortable with

When you get asked to make something, ask if they have a budget in mind. They might have no idea how much a custom, hand-made piece will cost. You could give them a range, based on materials and finishes, like a table made out of unfinished pine, versus a table made out of maple with an indestructible finish. If you’ve already sold something similar, let them know that price range.

Get a deposit if necessary

Once you have a project decided on, you may want to ask for a deposit, say 25% or 50%. If you really trust a friend or family, and you know they’ll buy whatever you end up with, it’s probably not necessary. But if you're dealing with a totally new customer and a big project, a deposit can show that you’re both serious about it. A deposit will also help pay for the materials. Once you’re underway, send a few photos of the project to show off the progress and let them know you’re working on it.

Stick to the quote, or less

In all this talk of how to price your DIY woodworking project, remember that it is much easier to lower your prices than raise them. Try your best to not go over your initial quote in materials or time. If things move quicker than expected or you got some materials on sale, you can always provide a discount at the end as a pleasant surprise. I’ve heard of people charging a “PITA tax,” or “Pain In The Ass tax,” (if the customer is very particular or change their mind a lot) but I prefer to quote on the high side and then provide a “better than expected” discount 🙂

Is this price reasonable?

You’ll also want to step back and ask yourself if the price you’ve arrived on is reasonable—would the average person feel like this is a fair price? Your price will most likely be higher than something they can buy at Ikea or Target, but look for other similar hand-made items to compare your price to. Without sounding preachy, try to convey the value in being handmade with solid materials and totally custom. Not a factory-made piece of particle board that will chip and get soggy over time. So, for an heirloom quality piece of furniture, does this price seem like something you would pay?

Examples of DIY woodworking projects to sell

You may already have some projects in mind, but I'll add a few below to get your wheels turning. Many of these I have already made and have tutorials and plans for—and there are a bunch more ideas on DIYPete.com. Feel free to use my plans in order to sell your own projects!

Small to large projects

Smaller projects can be better for trade shows and making a bunch of them even if they're not commissioned. They'll be a lower price point, so they can be more of an impulse buy for customers. Smaller projects are also much better for shipping if you want to sell over the internet. It's possible to ship larger projects but definitely gets expensive because the weight of solid wood gets heavy very quickly. And if you're integrating concrete or metal, shipping might cost more than it's worth. You could offer to deliver within a certain radius.

- Cutting board

- Birdhouse

- Drink caddy

- Toys

- Giant Jenga

- Kids furniture

- Doghouse

- Garden beds

- Cornhole board

- Chalkboard coat rack

- Custom shelving

- Bench

- Outdoor double chairs

- Farm table

- Outdoor concrete table

Places to sell or advertise your woodworking projects

In addition to word of mouth commissions, you can also sell things you make in a variety of places, but you’ll have to piece together a lot of efforts. Below is a quick list, followed by some explanations of places where you may be able to sell or advertise your DIY woodworking projects. Even if you don't plan to sell at these places, I'd still recommend checking some of them out because you might meet people who can help you with building your business or suggesting more places to sell.

- Gift shops

- Flea markets

- Arts fairs or festivals

- Etsy

- Craigslist or Facebook marketplace

- Yard sign

- Actual projects “For Sale” in yard

- Vehicle signage

Things to consider about each place

Local gift shops and flea markets may have lower barriers to entry and built in customers, but they will take a percentage of the sale.

Fairs or arts festivals can get you in front of your target audience, but you’ll need to pay for a booth, and be prepared with several items already finished to sell on site.

For smaller items that ship well, like cutting boards or toys, Etsy can be a great place with your target audience, just be ready with shipping supplies.

I wouldn’t really recommend Craigslist or Facebook Marketplace as a place to sell custom woodworking, because buyers will likely be looking to bargain. However, these are free places to list your items and could at least get a few interested folks.

There are also a ton of other online places where you can advertise for free, in addition to social media and Craigslist. You can advertise on Facebook, but maybe try to be a little more targeted by finding local Facebook Groups that you think might be interested. Join conversations and be a real person to gain organic exposure. Post nice photos to Instagram. Get active on Reddit and other forums in woodworking and local makers pages—they might have tips and resources to help you out.

And there’s always a yard sign (or actual furniture with a For Sale sign) or signage on your car that advertises your DIY woodworking side hustle. If you live on a busy street, a neat wood sign advertising that you make custom wood furniture could work well. Be sure to include your website or phone number.

Local demand

Supply and demand is a real force of economics, and will affect how to price your DIY woodworking projects. If your area has new people moving in and the cost of living is increasing, there should be good demand for quality custom furniture with a higher price tag. If there’s not a lot of money in your community, there might not be a great market for fancy woodworking, but you could still make basic items to suit your locals’ needs.

Turnaround time

Patience is really important while making a nice project—I have to remind myself sometimes! Be transparent with your customers and let them know a realistic timeline. If they need a piece extra quick, you can probably charge a little more. You might have to pay expedited shipping on supplies or run to the store a few extra times, and you might have to stay up all night working on it to get it done in time!

Don’t undercut other woodworkers

Be considerate of other woodworkers who are doing this as their full-time job—don’t underprice them too much. If you’re selling to just a few family and friends, you probably don’t have to worry, but if you start getting customers beyond your close circle, be sure to be respectful to other woodworkers. If your hobby is cutting into their livelihood, they won’t be very happy.

Conclusion: How to price your DIY woodworking projects

I hope this article can help you navigate the decision on how to price your DIY woodworking projects. It can feel a little strange at first, putting a price tag on your own time. But the more projects you get under your belt, the more comfortable you'll get with estimating the time it will take and naming your price. Selling woodworking projects as a side hustle can be fun and very rewarding; a way to follow your passion and your hobby to make a few extra bucks!

Cheers from Montana!

(DIY) Pete

This is awesome to read. Absolutely agree to consider those who are doing DIY as their full-time job. Electrician works are not far from this scenario, hence carefully choosing one from crelectrician.com is more convenient to do.

You are amazing!!! It really helps me a lot.

Thank you, I’m definitely going to keep this as a reminder when I need to compute for pricing the products.

The article is most important us.